Contrary to popular belief, the tailpipe emissions of vehicles only make up a very small percentage of pollutants. The truth is that steel—heavily used in car production—requires the most energy to make. That is why BMW believes that electrification is just the first step in achieving carbon neutrality. And to do that, the Munich-based carmaker needs partners in order to make its eco-friendly goal a reality.

Founded in 2020 and based in Norrbotten, Sweden, H2 Green Steel is one of the companies BMW has been looking for. It will use wind, hydroelectric energy, and hydrogen in producing steel. This process emits no carbon dioxide, with water as the only byproduct. H2 Green Steel will start operating in 2024 and is expected to make five million tons of environment-friendly steel by 2030.

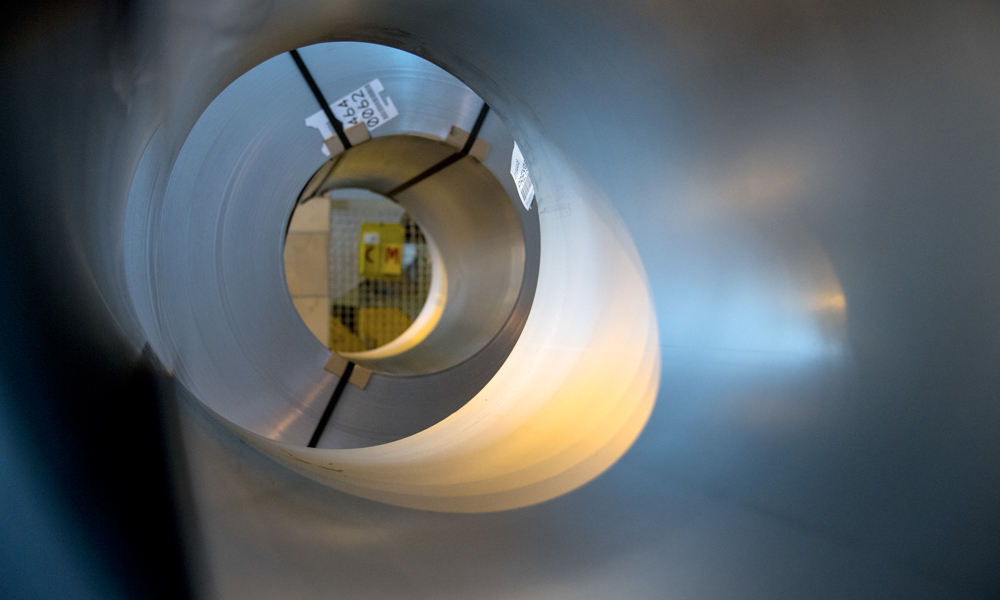

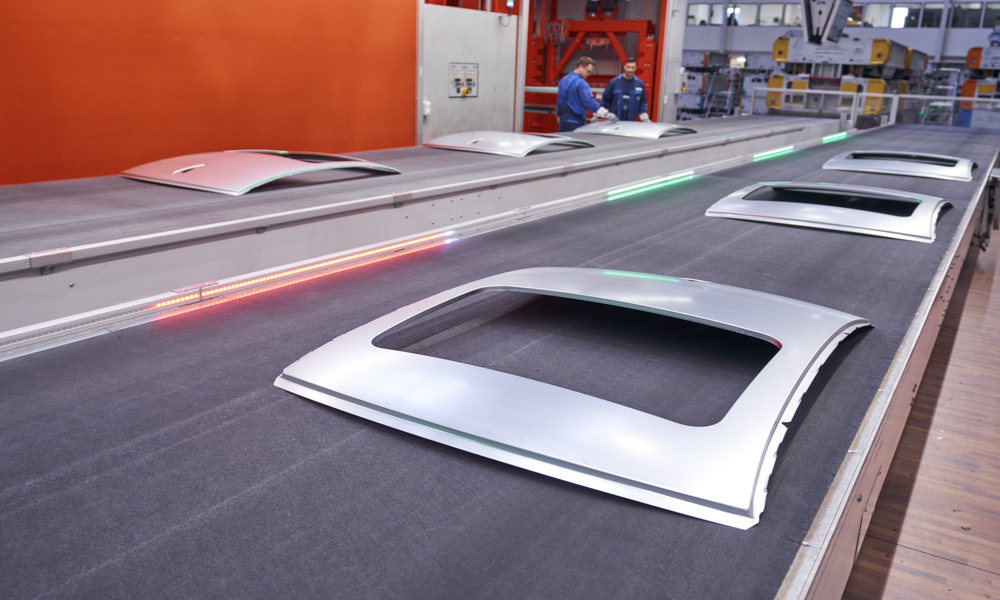

Both firms have already reached an agreement and BMW intends to start using steel supplied by the Swedish company for its vehicles beginning 2025. Furthermore, they will work together to create a closed-loop material cycle. BMW will send back discarded sheet metal from stamping plants. Then, H2 Green Steel will reprocess it to create new steel rolls. And since secondary steel uses less energy for processing, carbon-dioxide emissions will be lower by 50-80%.

Finally, BMW Group has also secured a deal with Northvolt, another Swedish company that produces battery cells. Like H2 Green Steel, the former only uses green electricity in making batteries. By 2024, the company will supply battery packs to be used in the BMW Group’s electrified vehicles.

Comments